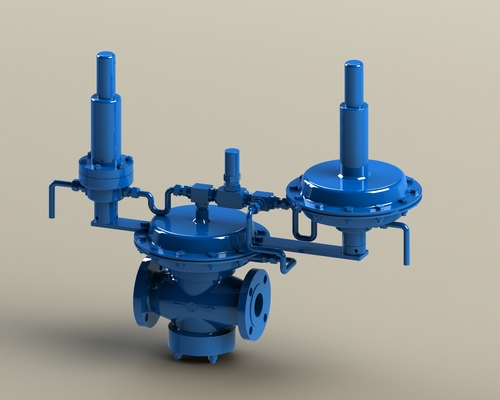

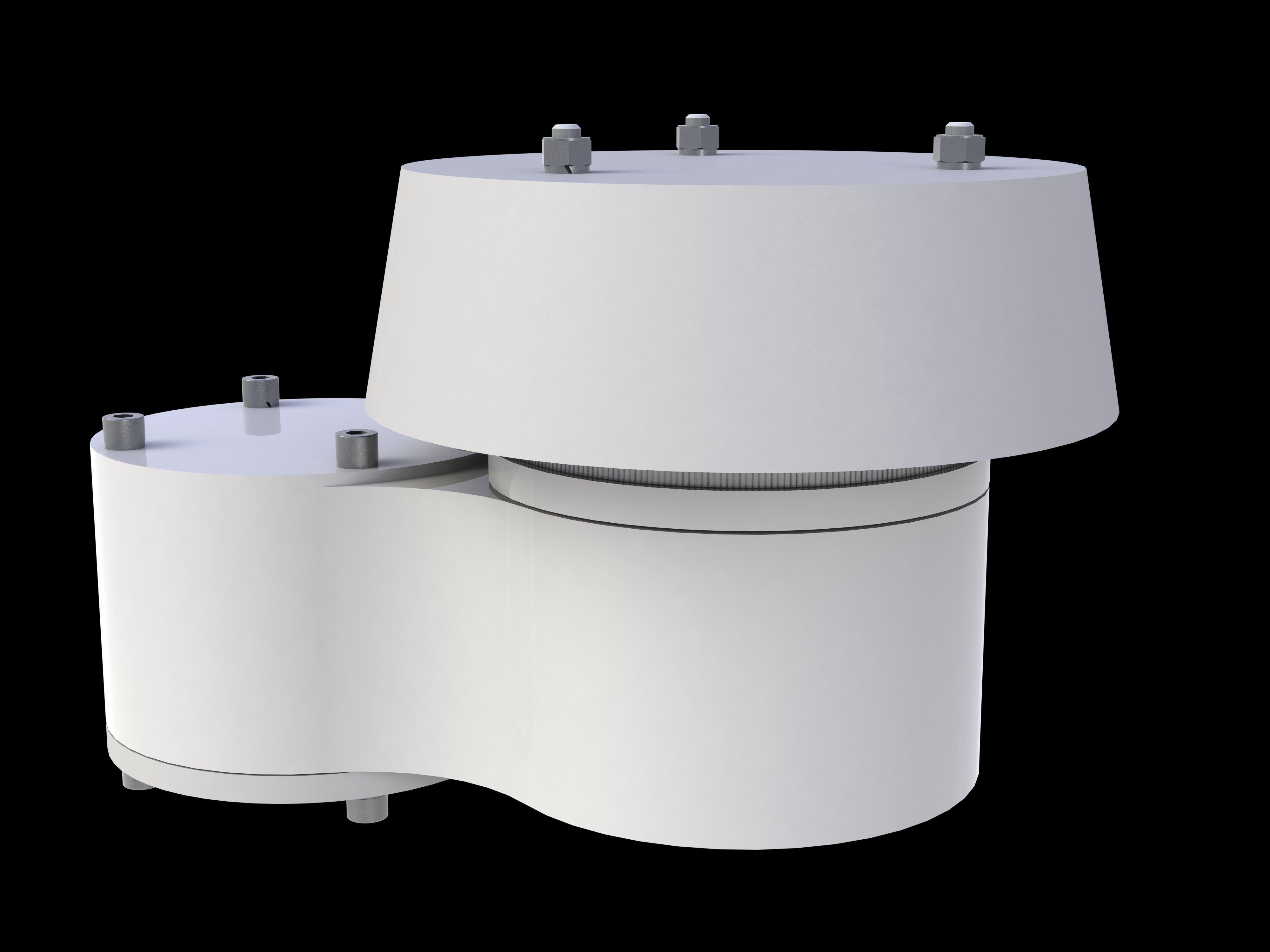

Breather Valves

Product Details:

- Feature Low Maintenance Cost High Performance High Efficiency

- Click to View more

Breather Valves Product Specifications

- Low Maintenance Cost High Performance High Efficiency

Breather Valves Trade Information

- Cheque

- Australia North America Eastern Europe Western Europe Africa Middle East South America Asia Central America

Product Description

|

BV-100 & BV-101 series valves are highly developed pressure and vacuum relief valves with excellent flow performance. These valves are relief valves for atmospheric tanks & vessels in which solvents are filled and drawn at a high flow rate. This valve is installed in the in-and out breathing lines of tanks, vessels and process equipments to protect against unpredicted fluctuations in pressure & vacuum. By retaining toxic vapors and avoiding atmospheric contamination, these valves provide increased fire protection and safety. Pressure cum vacuum relief breather valves are designed to protect tanks from possible casualty due to over pressure created by thermal expansion and product movement out of the tank and excessive vacuum created by thermal contraction and product movement out of the tank. At the same time it minimizes costly product evaporation / loss. Continued design improvements of these valves provide high efficiency, maximum flow capacity and minimum leakage. |

| Features |

|

Other Products in 'Process Industry' category

|

NIRMAL INDUSTIAL CONTROLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry