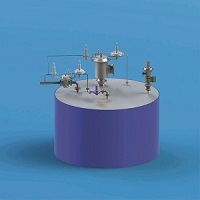

Tank Blanketing System

Product Details:

- Feature Low Maintenance Cost High Performance High Efficiency

- Click to View more

Tank Blanketing System Price And Quantity

- 01 Unit

Tank Blanketing System Product Specifications

- Low Maintenance Cost High Performance High Efficiency

Tank Blanketing System Trade Information

- Cheque

- Days

- Australia North America South America Eastern Europe Middle East Africa Western Europe Central America Asia

- All India

Product Description

Why Tank Blanketing?

In refineries & chemicals plants explosive hazards occur if air enters tanks containing volatile flammable liquid during pumping operation. When liquid is removed from a tank or an ambient temperature reduces, vacuum may develop.

Hence, for optimum protection of tank, contents and the environment, a low positive constant gas pressure is maintained in the vapor space of a storage tank. A blanketing gas, nitrogen being the most popular, serves to reduce the oxygen content in the vapor space, making it inert and eliminate the possibility of combustion. It also prevents the ingress of air and moisture from entering the storage vessel. When liquid is removed from tank or an ambient temperature reduces, vacuum may develop. Blanketing system prevents any vacuum from development and maintain the desired blanket pressure. In addition to this, a blanketing gas pressure reduces the evaporation of the stored product to a negligible amount. The result not only conserves product but also greatly reduces emissions. Quality of chemicals which gets affected by contact of moisture or oxygen, is protected by blanketing. These advantages are in addition to the fire protection that is provided.

KEY FEATURES

-

Turnkey Solution : We offer complete tank blanketing system with safety devices along with Nitrogen high pressure reducing station for storage tanks, reactors & centrifuges

-

Design : Simple, easy to maintain and reliable components. The complete system including all the safety features are designed, manufactured & commissioned, considering API-2000 requirements. The system incorporates pressure relief & vacuum breaking to protect the tank from over pressure and vacuum. Emergency pressure relief for protection in case of fire can also be incorporated. Continuous monitoring of oxygen contents in the tank & centrifuge can also be incorporated.

-

Low set point technology : Set point as low as inch w.c. (0.62 mBar), results in very low nitrogen consumption & operating cost.

-

Response : High speed response to protect the tank in the event of sudden surges.

-

System Accuracy : High accuracy where extremely low set point and minimal proportional band are important.

-

Extensive material selection and wide range of configurations :Different configurations are available depending on available nitrogen supply pressure, flow and controlled pressure requirements.

-

Proven technology :More than thousands of tanks are blanketed successfully over the years. Our clientele includes well known leaders in the field of refineries & petrochemicals, Pharmaceuticals & Pesticides, Fertilizers and others process industries. Some of fluids blanketed are:- Acetic acid, Orthoxylene, Chloroxylene, Ethylene, Naphtha, NGL, Benzene, Hexane, Cyclo-Hexane, Toluene, Methanol, Ethanol, Xyelene, Styrene, Ethyl Acetate, Ethyl Dichloride (EDC), Methyl Dichloride (MDC),Ethylene Oxide, carbon Sulfide, Aniline, Kerosene, Phynol, VCM, Tvlercaptan, lso Propyl Alcohol (IPA), Acetonitrile, Acetone, DM Water etc.

Other Products in 'Process Industry' category

|

NIRMAL INDUSTIAL CONTROLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry